Do you ever wonder why hand-knotted rugs take a long time to be made and why they are so expensive? Read on to find out ...

Famous in Iran and the Middle East, hand knotted rugs are made by hand-tying millions of knots on vertical strings, called the warp, on a frame/foundation. Knots are tied in rows, and before and after each row, a horizontal string, called weft, is passed through the warp and beaten down to compact the rows and give the rug a tight structure.

Rug weaver preparing vertical strings, called the warp on the foundation of the hand-made rug

Materials

Hand-knotted rugs are usually made of wool or silk.

Wool

Due to its accessibility, softness and durability, wool is the most commonly used material in hand-knotted rugs. Although camel, goat and sheep wool are usually used, sheep wool is generally of the highest quality and so the most used. What makes goat and camel wool less favourable is their resistance to dye.

To ensure it is the finest, sheep wool is shaven from the shoulder and under the belly of a lamb. Australian and New Zealand wool are the most popular and are commonly utilised but if not, the wool used in hand-knotted rugs comes from the sheep in high altitudes and cold areas. The best type of wool which could be used due to its extreme softness and durability, is Kurk or Kork wool.

Natural wool ropes on ready for hand-made rug knitting

Silk

Natural silk which is extremely fine and strong, comes from the cocoon of the silkworm. Silk is either utilised to weave the whole rug or is used in combination with wool to add depth to the rug and highlight certain characters on the design.

Silk rugs are very expensive and therefore, are mostly used as interior design elements and are hung on walls. If silk rugs are to be used to cover the floor, it is advised that they are used to decorate guest rooms where there is less traffic.

Dyed silk ropes for hand made rug. Before they are used in the knotting and weaving processes, both silk and wool are treated and dyed.

Design

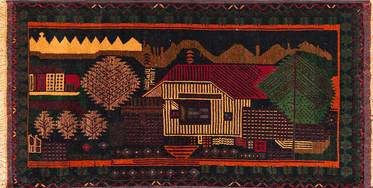

Even though a rug has to be designed before it is knotted and woven, in rural areas, this step is most of the time skipped, as the weavers imagine the design and knot it on the go to add to the authenticity and uniqueness of the design. In urban areas, however, the patterns are designed in advance and drawn on checkered paper. The units on the paper are then marked, coloured and glued on plywood, cardboard and chipboard for the weavers to follow when weaving. Through this, weavers can choose the correct colour for each knot.

Rug knitting

Rug knitting commences when the design is ready and the foundation is up with the warp. It can take up to months or even years to complete a rug, depending on the knot density and type.

Handwoven rug knot, Tabriz rug weaving style

Shaving and washing

After the completion of the knotting and weaving, the pile is shaved to the right height to make the design and the patterns expilicit, as a long pile will make it almost impossible for the design to be seen. The rug is then washed to remove any excess dye and debris.

When this process is complete, the rug is contolled for quality to ensure colour stability and lack of shrinkage; they are then shipped to rug bazaars or showrooms.